The industries are rapidly pacing up, working with expanding technology to diversify their portfolio. Moreover, it is the need of the hour to “outstand” in terms of functionality, utility, and performance. For evaluating the final testing phase, it is vital to create a replicated simulation environment to capture all the specifications under the ‘quality control test.’ Depending on the nature of the product, custom functional test fixtures serve effectively to meet the manufacturer’s needs.

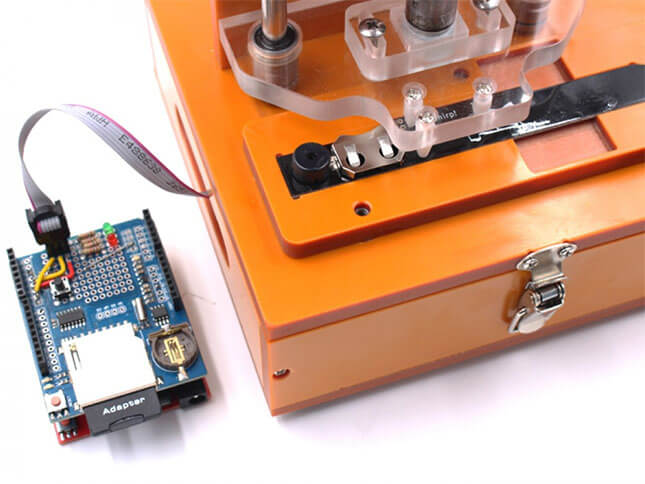

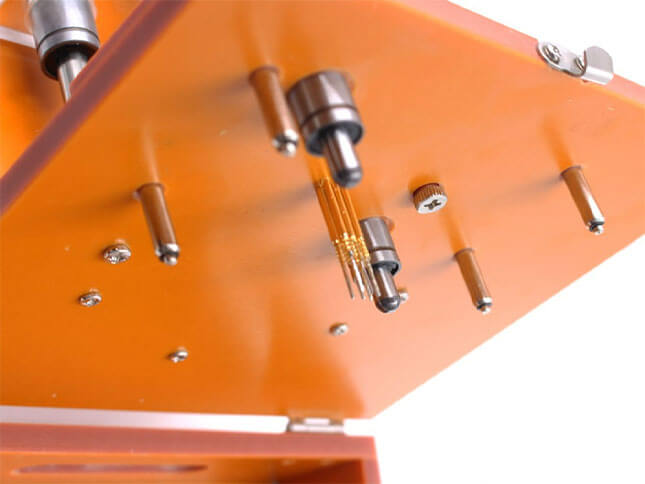

To optimize production yield, not only should the designs be manufacturable but also testable. Our Test Fixture is developed using hardware and firmware, using Beaglebone as the core processor in the test jig. The firmware is designed for text fixtures based on DUT (Device under Test) functionality tests, capable of validating hardware functionalities like impedance tests, peripheral tests(LEDs, Button, UART/I2C/SPI Interfaces, etc.), DUT firmware functionality tests.

The HDMI interface for display depicts the live status of the ongoing test result, making it a user-friendly process for easy understanding.