Quick Summary:

In this blog post, we will discuss how to choose the right battery management system for lithium ion batteries, focusing on the key metrics like the voltage, current, and BMS architecture.

Table of Contents

Introduction

Lithium-ion batteries are the power source for various gadgets around us. A report from ResearchandMarkets highlights that the global lithium-ion battery market was valued at 41.1 billion USD in 2021. By 2030, it is expected to reach 116.6 billion USD, with a growth rate of 12.3% CAGR from 2021 to 2030. The top features of Lithium-ion batteries are low self-discharge, high power, and reduced cost, making them one of the most suitable devices for energy storage.

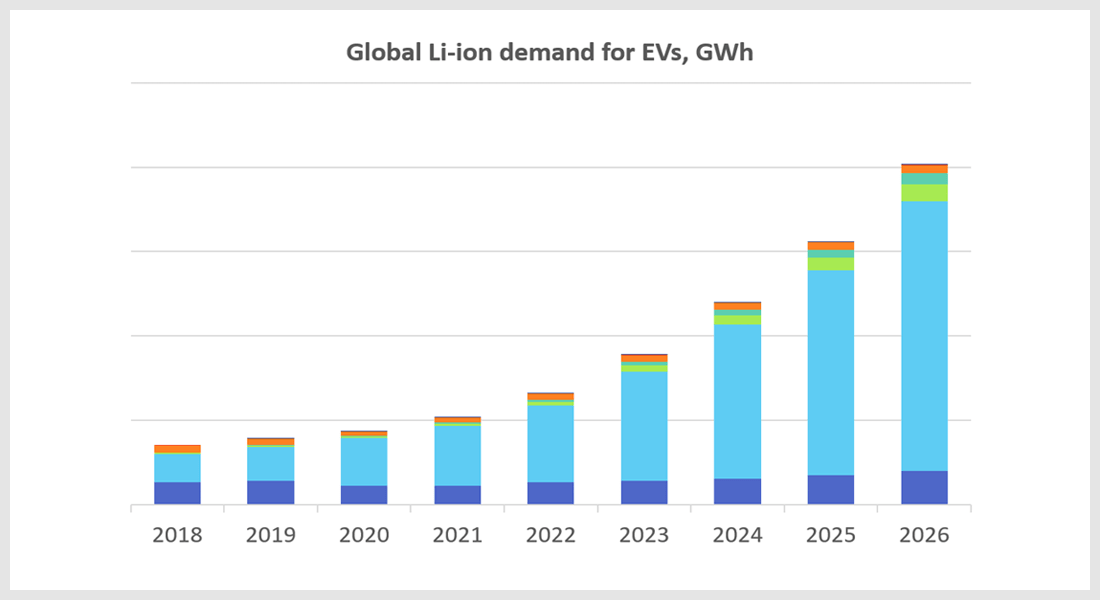

Over the years, the demand for Li-ion battery production has been increasing at a rapid rate. The applications of Li-ion are not just limited to the laptops and mobile phones we use; it is the building block in giving life to the heart of EV, i.e. Battery.

The performance of an electric vehicle relies on the battery pack it runs on. With multiple modules of cells constituting the whole grid of a power source, it is important to monitor every cell in the module. Each cell has a different operational state due to the difference in temperature, state of charge, and state of health.

A battery management system for electric vehicles is a sophisticated electronic circuit that ensures maximum protection, operational safety, and battery pack longevity. This results in an overall reliable, safe, and secured EV production, future-proofing the EV ecosystem.

Let’s analyze the key parameters necessary for selecting the right battery management system for lithium ion batteries.

Select the Right Battery Management System for Lithium ion Batteries

The selection of an accurate battery management system for lithium ion batteries depends on multiple factors such as understanding the voltage, current requirement, and topology.

1. Based on Voltage:

There are two types of classification based on voltage for battery management systems. They are low voltage and high voltage.

a. Low voltage:

Low voltage battery management system consists of voltage less than equal to 60V DC. Two-wheeler & three-wheeler range vehicles operate under a low voltage range.

b. High voltage:

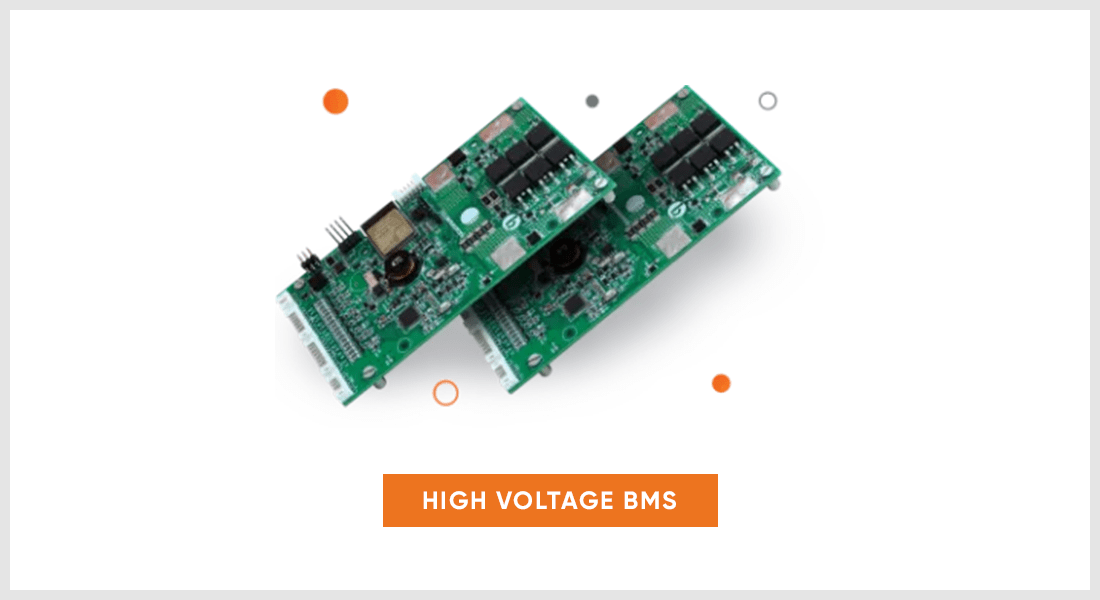

High voltage battery management system consists of a range less than equal to 900V and voltage less than equal to 1500V. Automotive vehicles mainly operate under high voltage ranges, such as four-wheelers, buses, and trucks. Other applications include energy storage systems.

2. Based on Topology:

There are many types of battery management systems based on topology. Depending upon the practical applications, there are mainly two types of architecture – centralized and decentralized battery management systems.

The centralized battery management system is the central controller unit responsible for monitoring, balancing, coordination, and cell control. The cell monitoring circuitry is connected to the intelligence circuitry in one single assembly. This intelligence circuitry unit facilitates internal communication with the cell monitoring unit to acquire the various data parameters and evaluate the battery’s State of Charge (SoC) and State of Health (SoH).

Secure your battery pack today with Bacancy’s smart BMS…!!

Our Battery Management System supports LiFePo4 and Li-ion battery packs as per your voltage requirements.

The decentralized battery management system has intelligence circuitry and cell monitoring divided into multiple modules. This model is implemented through modular, master-slave, and distributed topologies. It is interesting to note that as the voltage requirement of the vehicle increases, the complexities in handling, communication, and control significantly rise.

Adopting a decentralized battery management system for lithium ion batteries offers the following benefits:

- Precision in Measurement: Shorter wires cause lesser disturbance and attenuations, having high electromagnetic caliber.

- Reliability in Connection: With a decentralized architecture, the cell monitoring circuit is in the vicinity of the cells, proning it from mechanical vibrations and shocks.

- Increased Scalability: Cell stacking is simple in a decentralized architecture model. You can expand/reduce the operations by increasing or decreasing cell monitoring units.

Bacancy’s smart BMS for E-Bikes and E-Rickshaws

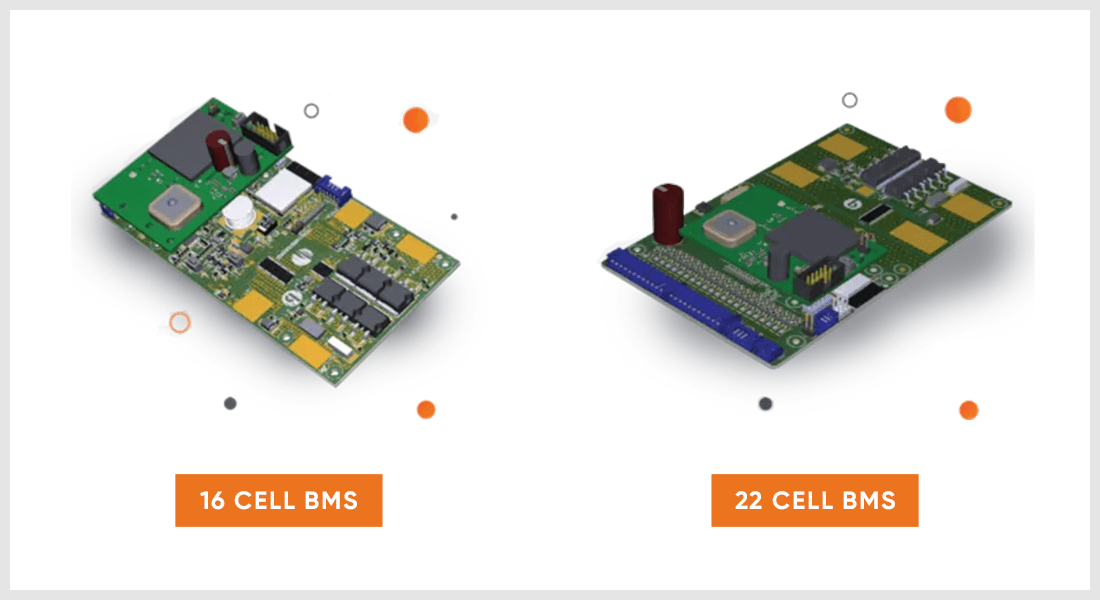

Our smart BMS technology optimizes the life of the battery pack through continuous monitoring and effective cell balancing by determining the accurate state of charge and state of health of the battery packs. Bacancy’s smart BMS supports the current range of 30/60/100 Amp as per the operational requirement for two-wheeler and three-wheeler applications such as Ebikes & ERickshaws.

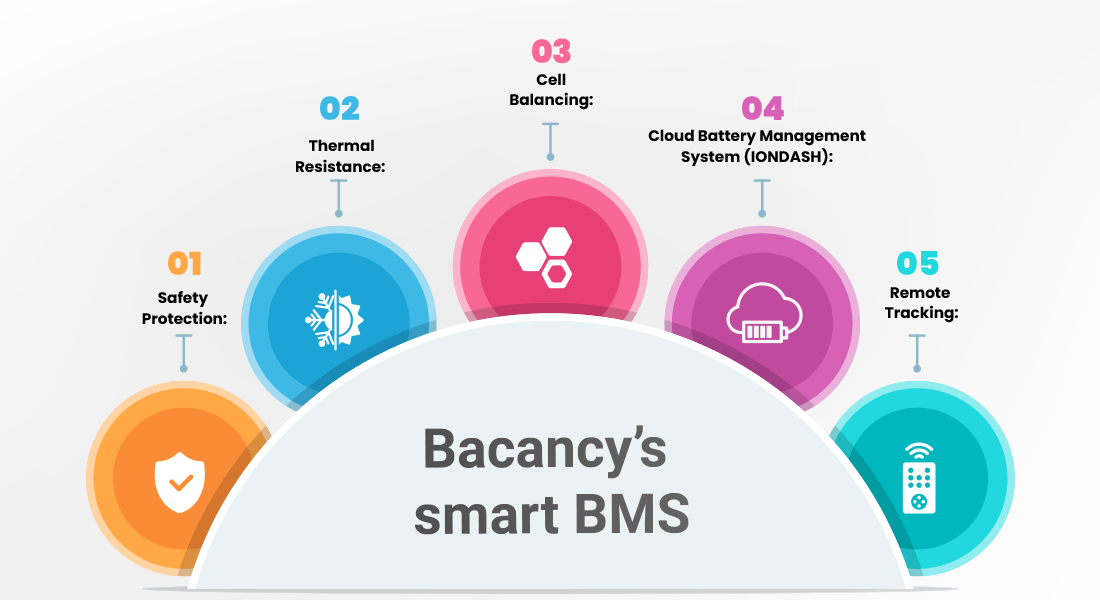

1. Safety Protection

Bacancy’s smart BMS is mechanically able to operate in a safety-regulated environment. These assurances include protection from heat accumulation and overheating, preventing catastrophic failures and fire accidents.

Continuous tracking and moderating the voltage, current, and temperature parameters regulate the battery operation in a safe, controlled area. Also, the electric vehicle is insured from battery damage situations or battery failure. The device displays alert notifications and fault diagnoses.

2. Thermal Resistance

The battery pack’s rugged and robust mechanical design offers 100% protection against thermal fluctuations, high impact forces, mechanical shocks, and vibrations.

3. Cell Balancing

Cell balancing enabled with both active and passive type cell balancing mechanisms ensures efficient energy utilization within the cells of a battery module. This increases the product life cycle of the electric vehicle, enhancing the concept of sustainable mobility solutions.

4. Cloud Battery Management System (IONDASH)

The battery management system for lithium ion batteries is the brain behind communication between the EV and battery pack and between the battery pack and charger. This enables high-performance-driven vehicles through efficient and timely balanced information amongst all the battery management system-enabled electric vehicle units.

5. Remote Tracking

Bacancy’s cloud-enabled battery management system, IONDASH, is a multipurpose platform for connecting multiple devices at once. It tracks the device’s state, whether it is charging, discharging, or ideal. The location tracking becomes easy for all the devices connected with IONDASH and is visible on the home page.

Final Thoughts

The battery management system for lithium ion batteries is crucial for assuring an EV battery pack’s safety, protection, reliability, and longevity in sustaining driving operations. With more diversification in the EV models using lithium-ion batteries, accurate selection of BMS for electric vehicles becomes the need of the hour.

So far you would have explored all the important parameters necessary for making an informed choice for your vehicle battery pack. Bacancy’s smart BMS covers a diverse product range from low to high voltages upto 500 V. Bacancy’s renowned venture Bacancy System is the leading product development and embedded service company. Tested under real conditions, our 16 cell BMS supports cell balancing at upto 130 mA of current. Get in touch with the top BMS Manufacturers in India.

Frequently Asked Questions (FAQs)

It is recommended to store the lithium ion batteries at a maximum charge of 30-50% for best results. However, if you are not using them for longer durations, then it’s better to store fully recharged batteries.

Usually, lithium-ion batteries have a life expectancy of upto two to three years that do not undergo complete charging cycles. Lithium-ion batteries which are rechargeable have a limited life and eventually lose their capacity to retain the charge. This battery aging is an irreversible process.

There are many external factors that affect battery life. In an ideal condition, it is simply the number of discharging/charging cycles before descending to 85% of the initial capacity. For e.g. a battery pack having 1100 cycles, has a life cycle of upto 5 yrs.

Bacancy’s smart BMS for LiFePO4 battery protects each cell in the battery and limits the voltage in the battery within a safe operational limit. Undervoltage during discharging is an alarming state, since cell voltage below 2.0 V may result in cell breakdown due to electrode damage.

Your Success Is Guaranteed !

We accelerate the release of digital product and guaranteed their success

We Use Slack, Jira & GitHub for Accurate Deployment and Effective Communication.